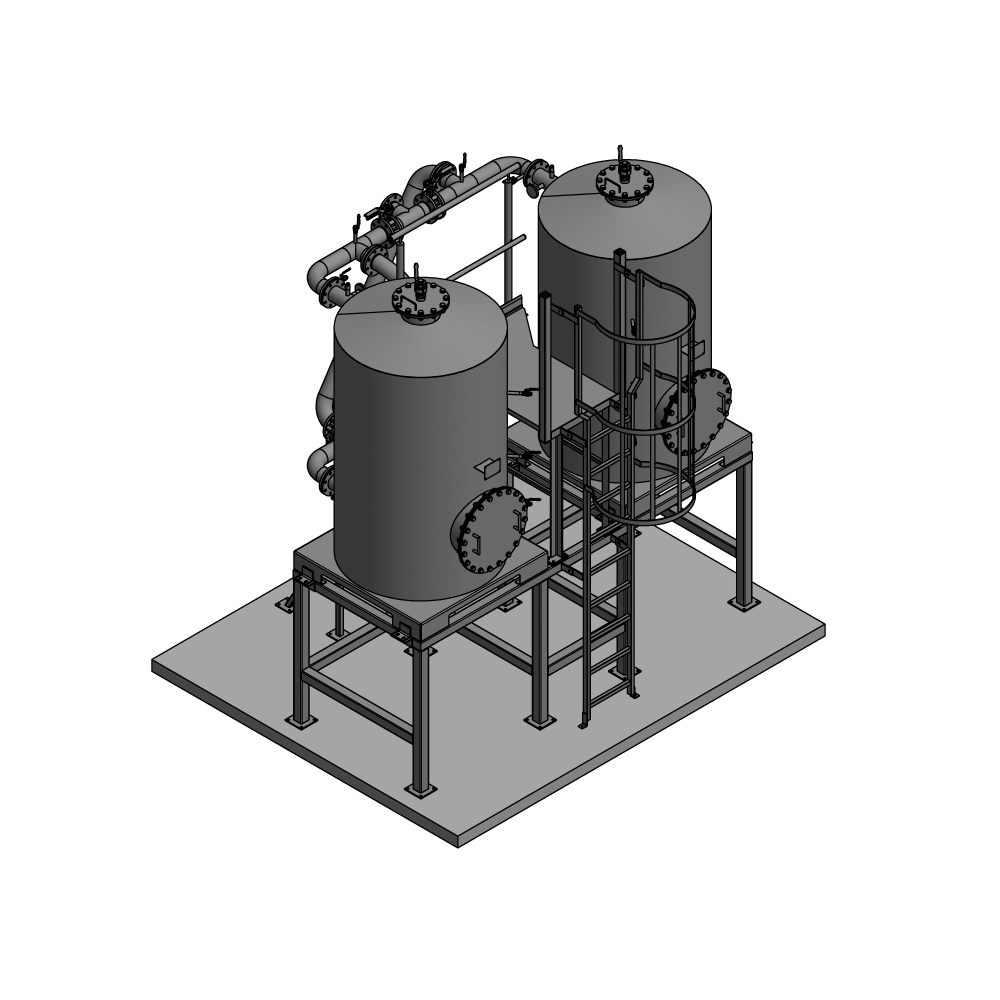

Services

Here's where we really impress:

With over 30 years of experience in handling and processing stainless steel, we are highly specialised in pipeline and plant construction for environmental and supply engineering. We place particular value on close and trusting cooperation with our customers. Thanks to many years of experience and our extensive know-how, we can offer individual solutions and thus meet our customers' expectations.